- Details

- Written by: Rose of Sharon DeVos

In today’s fast-moving digital economy, manufacturers and distributors can’t afford siloed systems or manual handoffs. A well-designed tech stack—spanning your e-commerce website, CRM, and ERP—becomes the backbone of seamless order processing, real-time visibility, and data-driven decision-making. Here’s how to structure that stack, choose the right partners, and integrate systems for optimal process flow.

1. Why a Unified Tech Stack Matters

-

Eliminate Data Silos: When your online store, sales team, and back-office live in separate worlds, critical order details get lost in translation. Integrations ensure that a customer’s purchase, payment, and shipping info flow automatically into your ERP—no re-keying, no errors.

-

Accelerate Order-to-Cash: Automated handoffs from Website → CRM → ERP mean invoices are generated the moment goods ship, and cash is applied to the right account immediately. You shorten days-to-payment, boost working capital, and delight customers with reliable fulfillment.

-

Gain Real-Time Insights: Consolidated dashboards draw from every layer of your stack. You see website conversion trends alongside inventory levels and production schedules—enabling proactive adjustments before stockouts or bottlenecks occur.

2. Building Block #1: E-Commerce Platform

Your front door to the market must be flexible, scalable, and integration-friendly. Consider:

| Platform | Strengths | Key Integration Considerations |

|---|---|---|

| Shopify | Quick to launch, extensive app ecosystem | Webhooks for order events, middleware like Celigo or Zapier |

| WooCommerce | Cost-effective, full control on-premise | REST API for orders, custom plugins to push data |

| PartTrap by ROIMA | Engineered for complex product configuration | Native ERP connectors, supports barcode label printing |

Best Practice: Choose a platform with open APIs and a partner marketplace. Early on, map out the data fields (SKUs, customer IDs, shipping methods) you’ll need downstream in CRM and ERP.

3. Building Block #2: Customer Relationship Management (CRM)

Once prospects land on your site, you need a system that nurtures leads and hands off qualified orders. A CRM linked to your website track traffic and interactions, letting you know which companies are worth a call or perhaps some well-timed, custom-curated email content or Google AdWords!

-

HubSpot CRM: Excellent for marketing automation, free tier, native e-commerce connectors.

-

Salesforce Sales Cloud: Enterprise-grade, highly customizable, robust partner network for custom integration.

-

Zoho CRM: Cost-effective, strong API coverage, good for mid-market.

Integration Tip: Use middleware (e.g., MuleSoft, Tray.io) or native connectors to sync customer records and order statuses. That way, when a web order arrives, your sales team sees the full purchase history, and when they update order stages, the ERP picks up the sales order automatically.

4. Building Block #3: Enterprise Resource Planning (ERP)

The ERP is the engine that handles inventory, purchasing, manufacturing, and financials. It's the heart of your business operations! Here are three examples of ERP's for a modest-sized distributor or manufacturer:

-

Acumatica: Cloud-native, good multi-warehouse support, RESTful APIs.

-

Microsoft Dynamics 365 Business Central: Strong distribution modules, seamless Office 365 integration.

-

Global Shop Solutions: Deep manufacturing functionality, barcode scanning, lot/serial traceability.

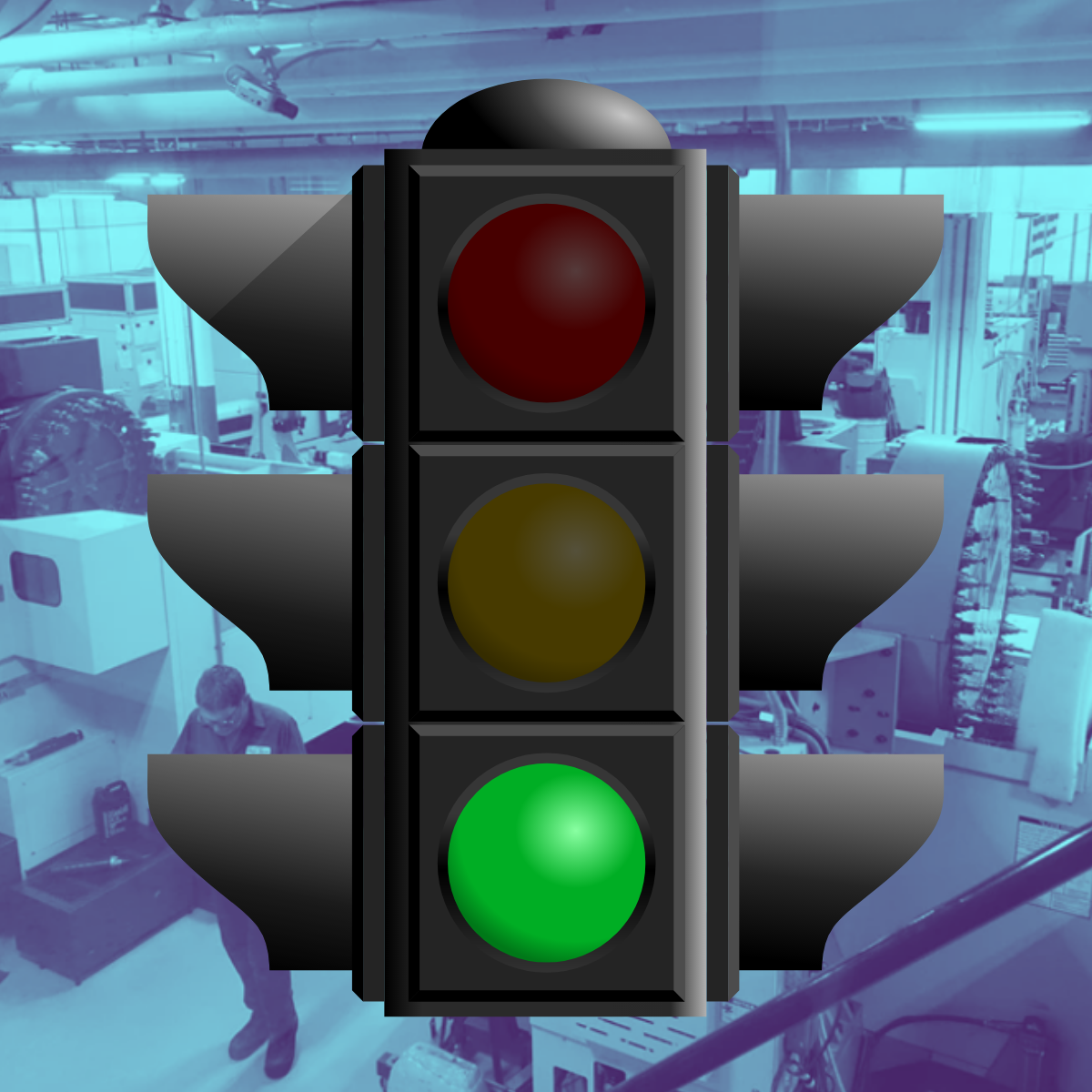

Integration Tip: Define event triggers—e.g., “When an order is placed, update the website stock levels for the parts." The ERP will have role-specific screens and tasks that keep you aware of when inventory falls below a critical re-order point, within the lead-time required to restock - so you keep the right inventory on hand.

5. Partner Selection: Beyond Software Licenses

-

Implementation Expertise: Look for partners who’ve done your exact industry and scale. They’ll know pitfalls around SKU counts, lot tracking, and e-commerce load.

-

Connectivity Focus: Your ideal integrator is as fluent in APIs and middleware as they are in ERP configuration. They’ll architect robust, monitored data pipelines—not fragile point-to-point hacks.

-

Ongoing Support & Roadmap: Technology evolves. Choose vendors and integrators who share a roadmap for new features (e.g., AI-driven demand forecasting, embedded chatbots) and offer managed services so your stack stays healthy.

6. Orchestrating the Flow

-

Customer Order: Placed on your e-commerce site → triggers a webhook.

-

Lead & Order Capture: CRM ingests customer data, creates or updates the contact record, and logs the order.

-

Sales Order Generation: CRM pushes order into ERP via middleware; ERP reserves inventory, schedules fulfillment.

-

Fulfillment & Shipping: ERP prints barcode labels, sends pick-pack instructions to the warehouse system, and updates shipment status.

-

Invoice & Payment: ERP auto-generates invoice, emails to customer, posts payment when received. CRM logs revenue against the contact record.

-

Analytics & Feedback: BI/dashboard tool pulls data from ERP, CRM, and e-commerce website to monitor KPIs—conversion rates, days sales outstanding (DSO), on-time delivery.

7. Best Practices & Pitfalls to Avoid

-

Data Governance: Agree on master data definitions (e.g., SKU formats, unit of measure) before you start.

-

Incremental Rollout: Don’t flip all integrations live at once. Pilot with a subset of SKUs or a single sales channel.

-

Error Handling: Built-in alerting for failed integrations (e.g., order didn’t land in ERP). Automated retries and exception dashboards are critical.

-

Security & Compliance: Ensure data in transit is encrypted, and that partners adhere to relevant standards (PCI DSS for payments, GDPR if you sell in Europe).

Conclusion

A best-in-class tech stack is more than a collection of tools—it’s an orchestrated ecosystem where your e-commerce storefront, CRM, and ERP operate as one. By selecting integration-friendly platforms, partnering with experts who understand both APIs and your industry, and designing clear data flows with governance and error handling, you transform fragmented steps into a seamless order-to-cash engine. The result? Faster fulfillment, happier customers, and the agility to scale as your business—and technology—evolves.

Ready to optimize your tech stack? Let’s discuss how IIoT Automating Solutions can architect and integrate the perfect E-commerce Website → CRM → ERP ecosystem for your distribution or manufacturing business.

- Details

- Written by: Rose of Sharon DeVos

Modern manufacturers depend on a suite of applications to manage their businesses effectively. Innovators are constantly thinking about the weak links and looking for solutions to improve efficiency without sacrificing quality. IoT (Internet of Things) and Industry 4.0 technologies offer new ways to speed up the flow of information, improve data accuracy, and predict problems. For smaller manufacturers, a great way to enter the IoT highway is with Direct Machine Data – or Machine Monitoring.

Read more: 5 Indicators You Are Ready for Direct Machine Monitoring

- Details

- Written by: Rose of Sharon DeVos

Manufacturers must pivot quickly.

I’m writing this article on April 16, 2020. The news is riveting. More than 22 million Americans have lost their jobs. Uncle Sam just made unrequested and greatly needed deposits in countless bank accounts. Many Americans are physically, spiritually and emotionally exhausted, working countless hours. And many others sit at home, warding off panic attacks, wonder how they will pay the bills and wishing they had work.

- Details

- Written by: Rose of Sharon DeVos

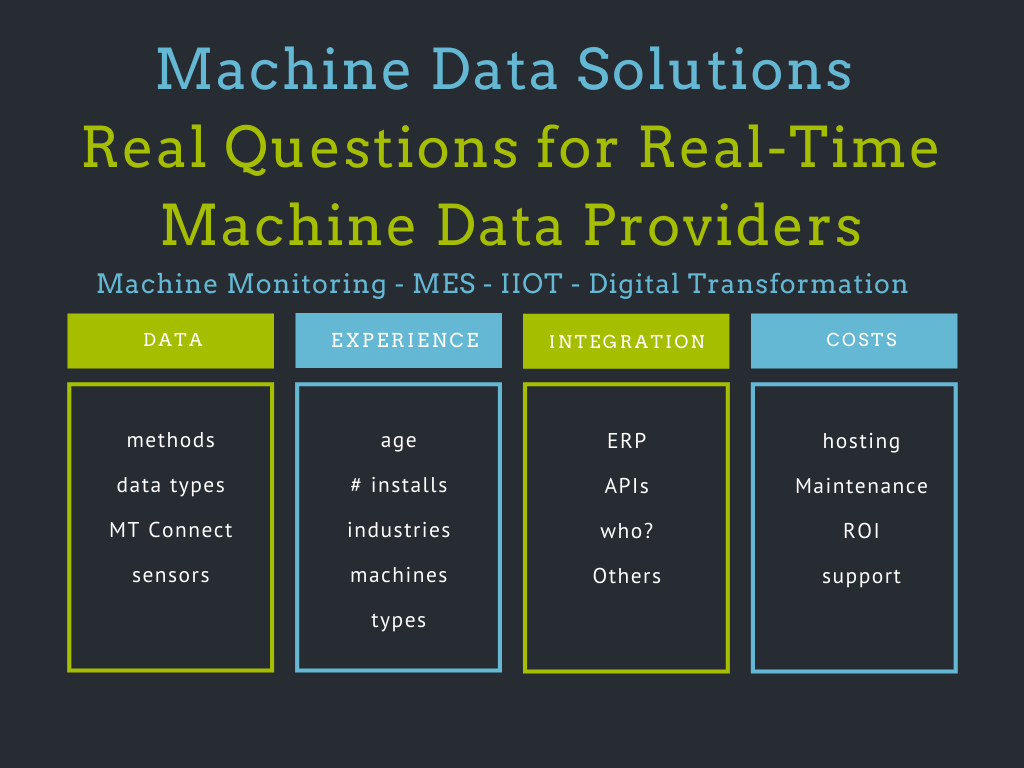

Things You Should Know to Decide on a Machine Data Solution Provider

Machine monitoring, Manufacturing Operations Management (MOM), Manufacturing Execution Systems (MES), Digital Transformation Strategy, Industry 4.0, Industrial Internet of things... No matter what you call it, it all requires using real-time machine data.

Read more: Things You Should Know Before Deciding on a Machine Data Solution

- Details

- Written by: Rose of Sharon DeVos

Right now, manufacturing is thriving in America, and many companies are investigating technologies that connect and collect data from equipment for real-time, actionable data. The field of options for machine monitoring software is getting more and more crowded. Almost everyone has heard that the future of manufacturing is IoT. But are the small to mid-size manufacturers convinced that IoT, smart manufacturing, and Industry 4.0 strategies are a necessity for them, or do they view it as a “want”?

Right now, manufacturing is thriving in America, and many companies are investigating technologies that connect and collect data from equipment for real-time, actionable data. The field of options for machine monitoring software is getting more and more crowded. Almost everyone has heard that the future of manufacturing is IoT. But are the small to mid-size manufacturers convinced that IoT, smart manufacturing, and Industry 4.0 strategies are a necessity for them, or do they view it as a “want”?

Read more: IIoT Data-Driven Manufacturing – Necessity or Want?